The LPG industry is growing with the rising consumption of LPG, a clean gas. To fill the demand-supply gap, LPG tank installation and LPG filling stations installation have also increased.

To begin with, LPG or Liquefied Petroleum Gas is a gas stored as a liquid in a gas tank. How? Pressure specifications allow engineers to store the gas in a liquid state. Low pressure is used for compressing the gas to a liquid.

How does the LPG tank work?

LPG appliances come with a mechanism that releases the pressure at the top of the LPG tank in a controlled manner. Through the mechanism, the LPG in the liquid form boils and receives enough heat to transform into the gaseous form for safe usage. An interesting thing to note here is that the LPG liquid boils at -42°C to turn into vapour.

LPG tanks are made of steel and this helps the liquid to gain heat from the ambient air for vaporization. If a higher amount of LPG gas is being used, there can be a formation of ice on the outer surface of the LPG tank.

Another amazing fact about LPG is that it is colourless and odourless. This feature of LPG can be dangerous for consumers. That’s why the composition of LPG is altered to ensure that there is an odour to alert the people handling the LPG gas in case of leakage.

Safety concerns in the LPG filling stations installation and tank installations

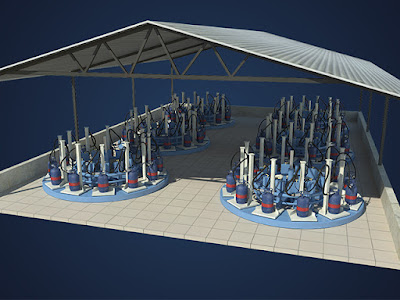

The design of the filling stations is planned after studying the location and weather conditions of the region. Depending on the vessel size, the vaporization rate is determined. LPG industry professionals refer to measurement tables for matching the size of vessels with the vaporization rate.

The Pressure relief valve is used for safer consumption of the LPG gas from LPG tanks or gas cylinders. Regulators are attached to control the flow of gas along with the valve.

If excessive pressure gets generated due to overfilling or due to rise in external temperatures then the pressure relief valve prevents the tank from rupturing. Thus, helping engineers to prevent an explosion that can cause damage to life and property.

Another thing to be noted is to be cautious about the level of pressure in the tank. In case, the gas vents out excess pressure then the LPG service provider should be immediately contacted from a safe distance away from the tank. Also, all personnel have to be instructed to stay away from the tank in such scenarios.

Some of the steps taken by an experienced service provider for installation of LPG filling stations are as follows:

- Assess the installation site for suitability of the installation. The area should not have other service lines passing through it posing as a barrier. The chosen spot should not be a flood-prone area.

- The site evaluation is completed and a report is generated.

- If the site is approved for installation, the design plan of the installation is created.

- Necessary approvals are taken from relevant authorities as per the laws applicable in the region before installation.

- Tested components such as pressure relief valves, regulators, pipes and other materials are used for successful installation of the approved filling station design plan by expert engineers and other personnel.

- Once the installation is complete, necessary test runs are carried out by safety officers to check the performance and safety of the LPG in operations.

- After operations commence at the LPG filling stations, LPG installation service providers offer maintenance services at periodic intervals as required.

To know more about professionally-managed LPG tank installation and filling stations installation services, call AEPL at 1800 266 6936.

No comments:

Post a Comment